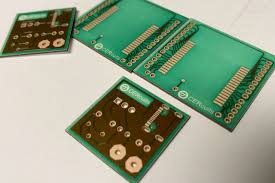

Alumina PCBs

Antennas in mobile devices play a pivotal role in performance, connectivity, and efficiency. They are designed to support high data rates and provide robust wireless transmissions. The challenge lies in integrating them in smaller, compact platforms with minimal footprints and lower cost. The design of phased-array antennas in particular poses unique challenges for PCB manufacturing. It requires complex circuits with a higher density of interconnects and a higher operating temperature range.

To help address these challenges, many designers are turning to alumina substrate PCBs. These boards are made of a ceramic material that has good thermal conductivity and electrical insulation properties. They can withstand high-temperatures without delaminating, and are resistant to thermal expansion and stress. This makes them an excellent choice for the manufacturing of phased-array antennas.

In alumina pcb, copper layers are directly bonded to the alumina core in a process similar to DBCs (Dielectric Barrier Co-fired). This direct interface facilitates efficient heat transfer and resists oxidation at elevated temperatures. The alumina-copper interface also allows the fabrication of multilayer boards with intricate routing patterns and planes. The copper thickness can range from 0.7 to over 3oz and follows the same circuit pattern etching as standard FR-4 boards.

Alumina PCBs for Phased-Array Antennas

As the copper traces on alumina PCBs are etched, they must be compensated for in order to achieve a precise width. This is done to avoid the occurrence of shorts and opens that may arise due to uneven etching. The alumina also adds a level of stability to the board and protects against mechanical stresses and dimensional variations.

Unlike traditional metals, aluminum is a light-weight element that helps reduce the overall weight of the circuit board. In addition to this, it has the ability to dissipate heat from vital components on the circuit board, thereby protecting them from any damage. This is one of the main reasons why alumina substrate PCBs are popular in applications where reliability and safety are critical.

Alumina PCBs are able to provide long working lifespans of up to 50 years and have been formulated for use in harsh environments. These factors make them an ideal solution for specialized, high-reliability electronics. Tight material and dimensional control during production ensures that defects and latent faults are kept to a minimum, which in turn improves the mean time between failures.

Alumina PCBs are suitable for a wide range of applications, but they are particularly suited to high-power, high-speed devices that require a robust power supply. Moreover, they can be used in medical devices that must operate in close proximity to human tissue. However, it is important to consult with a specialist prior to purchasing these products. This will ensure that you are obtaining the right product for your needs. Additionally, the expert will be able to answer any queries you have about the product. This will help you get the best quality product at an affordable price. The expert will be able to give you advice about the best alumina pcb manufacturers to suit your requirements.